- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

All you Need to Know About Nickel Alloy Round Bars

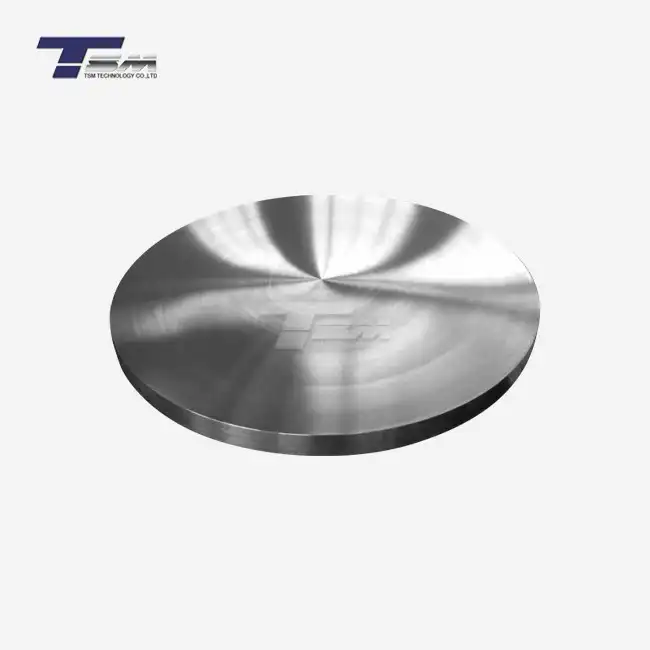

Navigating the world of superior alloys can feel like stepping into uncharted territory, especially when it comes to selecting the right materials for precision engineering projects. Nickel alloy round bars, renowned for their resilience and versatility, stand out as a cornerstone in industries ranging from aerospace to marine engineering. These robust components, including variants like the nickel 200 round bar, offer unparalleled resistance to corrosion, extreme temperatures, and mechanical stress. Whether you're a machine shop owner or an engineer sourcing materials globally, understanding the nuances of these alloys is paramount. This article unravels the essentials, spotlighting their properties, applications, and why partnering with a trusted supplier like TSM Technology Co., Ltd. ensures quality and reliability.

Unveiling the Properties of Nickel Alloy Round Bars

Exceptional Corrosion Resistance

Nickel alloy round bars are celebrated for their ability to withstand corrosive environments that would erode lesser materials. This attribute stems from the high nickel content, which forms a protective oxide layer on the surface, shielding the metal from degradation. In sectors like chemical processing, where exposure to acidic or alkaline substances is routine, this resistance proves invaluable. Variants such as the nickel 200 round bar excel in environments laden with caustic soda or hydrochloric acid, ensuring longevity and reducing maintenance costs. By opting for these alloys, industries can safeguard their equipment against premature failure, enhancing operational efficiency.

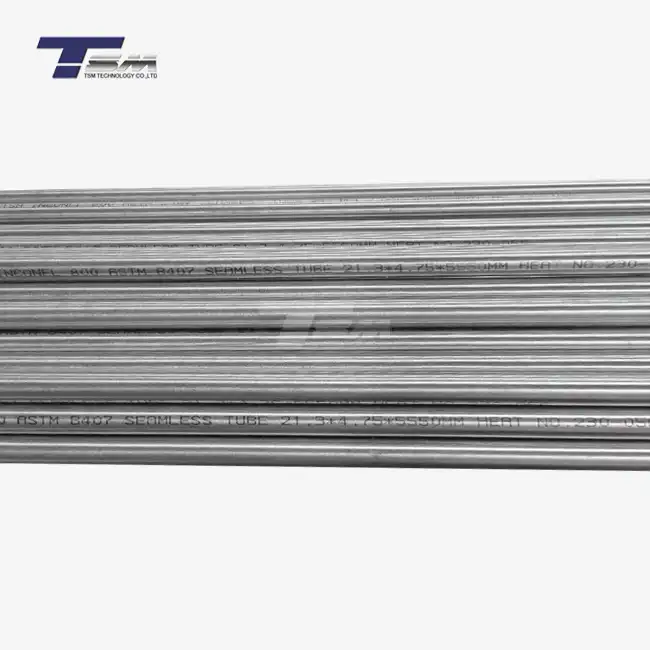

High-Temperature Performance

Another hallmark of nickel alloy round bars is their capacity to endure extreme heat without compromising structural integrity. Alloys like Inconel and Hastelloy, often available in round bar form, maintain strength and stability at temperatures exceeding 1000°C. This makes them indispensable in applications such as gas turbines, jet engines, and power generation plants, where thermal stability is non-negotiable. The ability to resist oxidation and scaling at elevated temperatures ensures that these components deliver consistent performance, even under the most arduous conditions, making them a preferred choice for engineers worldwide.

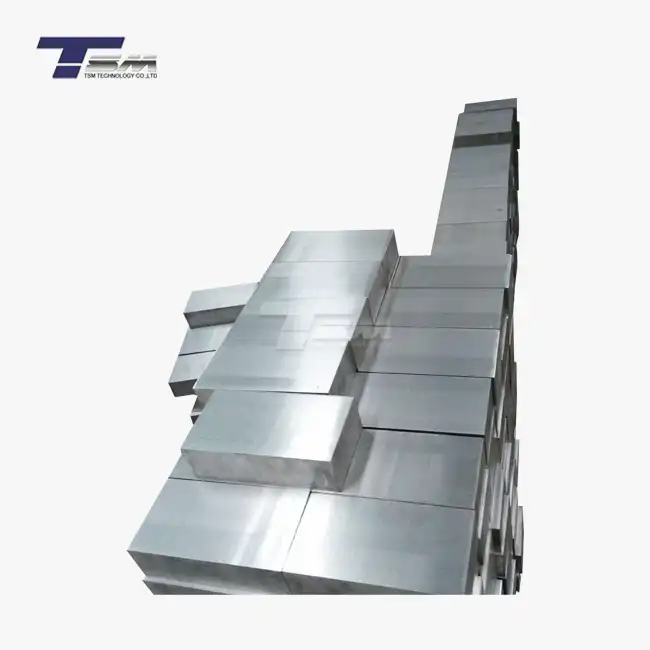

Mechanical Strength and Durability

Beyond corrosion and heat resistance, nickel alloy round bars boast formidable mechanical strength, making them suitable for high-stress applications. Their ductility allows for intricate machining, while their toughness ensures they can withstand significant wear and tear. Monel alloys, as an example, are prized in marine engineering for their ability to resist seawater corrosion while enduring the mechanical stresses of underwater structures. This blend of durability and malleability positions nickel alloy round bars as a versatile solution across diverse industries, from oil and gas to precision manufacturing.

Applications of Nickel Alloy Round Bars Across Industries

Aerospace and Defense

In the aerospace sector, the demand for materials that can endure extreme conditions while maintaining precision is unrelenting. Nickel alloy round bars, including specialized grades like Inconel, are integral to the fabrication of turbine blades, exhaust systems, and structural components. Their ability to resist thermal fatigue and creep under high stress ensures the safety and reliability of aircraft and spacecraft. The nickel 200 round bar, with its excellent electrical conductivity, also finds use in electronic components within this sector, highlighting the versatility of these alloys in meeting stringent aerospace standards.

Oil and Gas Exploration

The oil and gas industry operates in some of the harshest environments on Earth, from deep-sea drilling rigs to desert refineries. Nickel alloy round bars are pivotal in this domain, offering resistance to sour gas environments and high-pressure conditions. Hastelloy variants, renowned for their ability to combat pitting and stress corrosion cracking, are often machined into valve stems, pump shafts, and drilling tools. This resilience not only extends the lifespan of critical equipment but also minimizes downtime, a crucial factor in an industry where operational continuity is paramount.

Marine and Chemical Processing

Marine engineering and chemical processing present unique challenges, with constant exposure to corrosive elements like seawater and aggressive chemicals. Nickel alloy round bars, particularly Monel and nickel 200, are tailored to thrive in these conditions. In marine applications, they are used in propeller shafts, fasteners, and heat exchangers, resisting the relentless assault of saltwater. In chemical plants, these alloys are shaped into reactor vessels and piping systems, ensuring the safe handling of volatile substances. Their adaptability to such demanding environments underscores their value in safeguarding operational integrity.

Choosing the Right Nickel Alloy Round Bar for Your Needs

Understanding Alloy Grades

Selecting the appropriate nickel alloy round bar begins with understanding the distinct properties of various grades. Inconel alloys, as an example, are ideal for high-temperature applications, while Monel excels in marine environments. Nickel 200 round bars, with their purity and conductivity, are suited for electrical and chemical applications. Each grade offers a unique combination of attributes, and matching these to your project's requirements is essential. Consulting with a supplier like TSM Technology Co., Ltd., which specializes in superior alloys, can provide clarity, ensuring you select a material that aligns with your operational demands.

Quality Assurance and Standards

The performance of nickel alloy round bars hinges on their quality, making rigorous inspection and adherence to standards non-negotiable. Reputable suppliers implement stringent quality control systems, subjecting each bar to meticulous testing for dimensional accuracy, surface integrity, and metallurgical consistency. Certifications such as ASTM and ASME serve as benchmarks, guaranteeing that the materials meet global industry standards. TSM Technology Co., Ltd., with its 14-year legacy, exemplifies this commitment, ensuring that every product, from Hastelloy to Incoloy, undergoes thorough scrutiny, delivering reliability to precision engineering and machine shops worldwide.

Partnering with a Trusted Supplier

The global market for superior alloys is vast, but not all suppliers offer the same level of expertise or quality. Partnering with a seasoned provider like TSM Technology Co., Ltd. offers distinct advantages, from access to innovative alloys to tailored solutions for specific applications. Since its inception in 2011 in Hong Kong, TSM has cultivated a reputation for excellence, driven by a passion for advancing material science. Their dedication to developing new alloys and enhancing existing ones ensures that customers receive cutting-edge materials backed by unparalleled support, making them a trusted ally in your engineering endeavors.

Conclusion

Nickel alloy round bars are a linchpin in industries demanding resilience, precision, and longevity. From their exceptional corrosion resistance to their versatility across aerospace, oil and gas, and marine applications, these materials are indispensable. Choosing the right grade and supplier is crucial to harnessing their full potential. With TSM Technology Co., Ltd., you gain access to superior alloys crafted with precision and backed by rigorous quality standards, ensuring your projects thrive in the most challenging environments.

Contact Us

Ready to elevate your projects with top-tier nickel alloy round bars? Contact TSM Technology Co., Ltd. today at info@tsm-technology.com to explore our range of superior alloys and discover how we can support your engineering needs.

References

Smith, J. A., & Patel, R. K. (2020). Advanced Materials in Engineering: The Role of Nickel Alloys in High-Stress Applications. Journal of Material Science and Engineering.

Thompson, L. M. (2019). Corrosion Resistance of Nickel-Based Alloys in Harsh Environments. International Journal of Chemical Engineering.

Kumar, S., & Lee, H. (2021). High-Temperature Performance of Inconel and Hastelloy Round Bars. Aerospace Materials Review.

Brown, E. T. (2018). Applications of Monel Alloys in Marine Engineering. Journal of Ocean Technology.

Davis, M. R., & Singh, P. (2022). Quality Standards in Nickel Alloy Manufacturing. Global Engineering Standards Digest.

Chen, Y., & Gupta, A. (2020). Innovations in Nickel Alloy Development for Precision Engineering. Materials Innovation Quarterly.

Learn about our latest products and discounts through SMS or email