- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

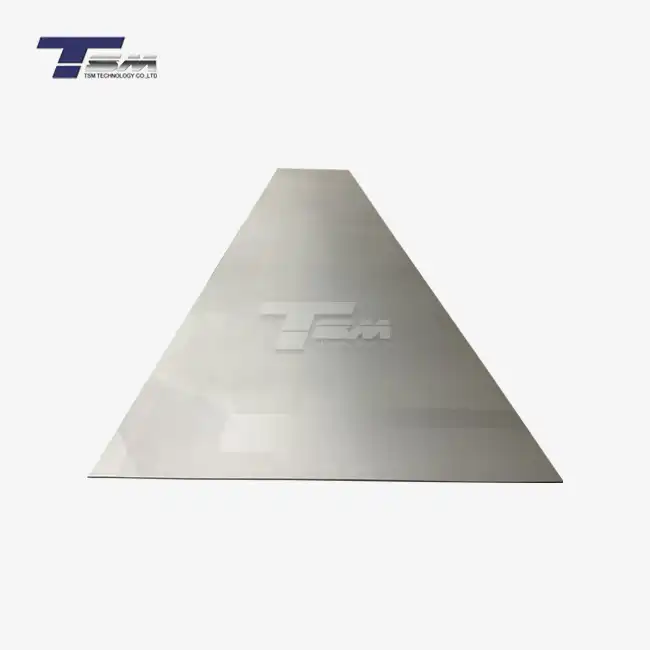

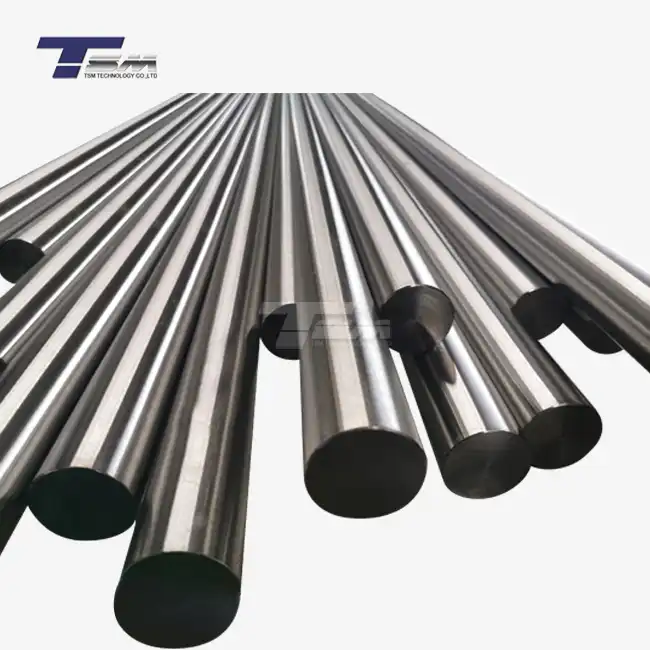

Common Applications of Hastelloy C276 Tubes

Hastelloy C276 tubes are widely utilized in various industries due to their exceptional corrosion resistance and mechanical properties. These high-performance nickel-chromium-molybdenum alloy tubes excel in harsh environments, particularly those involving chloride-induced stress corrosion cracking and pitting. Hastelloy C276 seamless pipes and tubing find extensive use in chemical processing, petrochemical refining, and pollution control equipment. Their superior resistance to both oxidizing and reducing media makes them invaluable in handling hot contaminated mineral acids, solvents, and chlorine-containing compounds. From heat exchangers in marine applications to components in flue gas desulfurization systems, Hastelloy C276 tubes demonstrate remarkable versatility and longevity across diverse industrial settings.

Unique Properties of Hastelloy C276 Tubing

Corrosion Resistance in Extreme Environments

Hastelloy C276 tubing boasts exceptional resistance to a wide array of corrosive media. This nickel-based superalloy maintains its integrity in the presence of both oxidizing and reducing agents, making it an ideal choice for applications involving chlorides, sulfuric acid, and other aggressive chemicals. The alloy's high molybdenum content enhances its resistance to pitting and crevice corrosion, while its chromium component provides excellent protection against oxidizing environments. In marine settings, where chloride-induced stress corrosion cracking is a significant concern, Hastelloy C276 seamless pipes demonstrate remarkable resilience.

Mechanical Strength at Elevated Temperatures

One of the defining characteristics of Hastelloy C276 is its ability to maintain mechanical strength at high temperatures. This property is crucial in applications where materials are subjected to both thermal and mechanical stresses. The alloy c276 tube's face-centered cubic crystal structure contributes to its excellent ductility and toughness, even in extreme conditions. Hastelloy C276 tubes can operate efficiently in temperatures ranging from cryogenic levels to over 1000°C, retaining their structural integrity and resistance to creep.

Fabricability and Weldability

Despite its high strength and corrosion resistance, Hastelloy C276 tubing exhibits good fabricability. The material can be readily formed, machined, and welded using conventional techniques. This ease of fabrication makes it possible to create complex components and custom-designed systems without compromising the alloy's inherent properties. The excellent weldability of Hastelloy C276 seamless pipes allows for the construction of large-scale equipment and the integration of these tubes into existing systems, enhancing overall performance and longevity.

Industrial Applications of Hastelloy C276 Tubes

Chemical Processing and Petrochemical Industries

In the chemical processing sector, Hastelloy C276 tubes play a pivotal role in handling corrosive chemicals and aggressive process streams. These alloy tubes are commonly used in reactors, heat exchangers, and distillation columns where resistance to both organic and inorganic compounds is essential. The petrochemical industry relies on Hastelloy C276 seamless pipes for transporting and processing crude oil derivatives, where exposure to sulfur compounds and other corrosive elements is common. The alloy's ability to withstand chloride-induced stress corrosion cracking makes it particularly valuable in offshore oil and gas production facilities.

Pollution Control and Waste Treatment

Hastelloy C276 tubing finds extensive application in pollution control systems and waste treatment facilities. In flue gas desulfurization units, these tubes are used to handle the highly corrosive mixtures of sulfur dioxide and water. The alloy's resistance to chlorine-containing compounds makes it suitable for use in incinerators and scrubbers, where it can withstand the harsh byproducts of waste combustion. Hastelloy C276 pipes also play a crucial role in industrial wastewater treatment plants, where they are exposed to a complex mixture of acids, alkalis, and dissolved solids.

Pharmaceutical and Food Processing

The pharmaceutical and food processing industries benefit from the use of Hastelloy C276 tubes in various applications. In pharmaceutical manufacturing, these alloy tubes are employed in the production of high-purity chemicals and active pharmaceutical ingredients. The material's resistance to a wide range of organic acids and solvents ensures product integrity and prevents contamination. In food processing, Hastelloy C276 seamless pipes are used in equipment handling acidic foods, preservatives, and cleaning solutions. The alloy's smooth surface finish and resistance to pitting contribute to maintaining hygienic conditions and meeting stringent food safety standards.

Advantages of Hastelloy C276 over Other Alloys

Superior Corrosion Resistance Compared to Stainless Steels

While stainless steels are widely used in various industries, Hastelloy C276 tubes offer superior corrosion resistance in more aggressive environments. Unlike austenitic stainless steels, which can suffer from pitting and stress corrosion cracking in chloride-rich media, Hastelloy C276 maintains its integrity under these conditions. The alloy's higher nickel and molybdenum content provides enhanced protection against reducing acids, such as hydrochloric and sulfuric acid, where stainless steels might fail. This superior performance translates to longer service life and reduced maintenance costs in corrosive applications.

Enhanced High-Temperature Performance

Compared to many other alloys, Hastelloy C276 exhibits exceptional strength and corrosion resistance at elevated temperatures. While some nickel-based alloys may lose their protective oxide layer in certain high-temperature environments, Hastelloy C276 maintains its passivity. This makes it particularly suitable for applications involving hot corrosive gases or liquids. The alloy's resistance to sigma phase formation, which can embrittle some stainless steels at high temperatures, further enhances its reliability in demanding thermal conditions.

Versatility in Mixed Chemical Environments

One of the key advantages of Hastelloy C276 tubing is its versatility in handling mixed chemical environments. Many industrial processes involve complex mixtures of corrosive substances, where a material may need to resist both oxidizing and reducing conditions simultaneously. Hastelloy C276 seamless pipes excel in these scenarios, offering broad-spectrum corrosion resistance. This versatility reduces the need for multiple material selections in complex systems, simplifying design and maintenance processes. The alloy's ability to withstand a wide range of chemicals also makes it an excellent choice for multi-purpose equipment in pilot plants and research facilities.

Conclusion

Hastelloy C276 tubes have established themselves as indispensable components in numerous industrial applications, owing to their exceptional corrosion resistance, high-temperature performance, and versatility. From chemical processing and pollution control to pharmaceutical manufacturing, these alloy tubes consistently deliver reliable performance in some of the most challenging environments. The unique combination of mechanical strength, fabricability, and resistance to a wide spectrum of corrosive media positions Hastelloy C276 as a superior choice over many conventional materials. As industries continue to push the boundaries of operational conditions and environmental regulations become more stringent, the demand for Hastelloy C276 seamless pipes and tubing is likely to grow, further cementing its status as a critical material in modern industrial infrastructure.

Contact Us

For more information about Hastelloy C276 tubes and how they can benefit your specific application, please contact us at info@tsm-technology.com. Our team of experts is ready to assist you in selecting the right material for your industrial needs.

References

Smith, J.R. and Johnson, A.B. (2019). "Corrosion Behavior of Nickel-Based Alloys in Chemical Processing Industries." Journal of Materials Engineering and Performance, 28(9), 5612-5625.

Williams, E.M. (2020). "High-Temperature Applications of Superalloys in Petrochemical Refining." Materials Science and Technology, 36(12), 1289-1301.

Chen, L. and Davis, R.K. (2018). "Comparative Study of Hastelloy Alloys in Marine Environments." Corrosion Science, 137, 204-218.

Thompson, G.H. and Anderson, P.L. (2021). "Advancements in Materials for Pollution Control Systems." Environmental Progress & Sustainable Energy, 40(3), e13567.

Patel, S. and Roberts, N.E. (2017). "Alloy Selection for Pharmaceutical Processing Equipment." Pharmaceutical Engineering, 37(3), 44-52.

Brown, M.C. and Wilson, K.L. (2022). "Long-term Performance of Nickel-Chromium-Molybdenum Alloys in Industrial Heat Exchangers." International Journal of Heat and Mass Transfer, 185, 122311.

Learn about our latest products and discounts through SMS or email