- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Strong is Nickel Alloy Sheet?

When pondering the robustness of a nickel alloy sheet, the answer lies in its exceptional mechanical prowess. These sheets, crafted from superior alloys like Monel, Inconel, and Hastelloy, boast tensile strengths often exceeding 100,000 psi, with some variants like Inconel 718 reaching up to 180,000 psi under optimal conditions. Their durability stems from a unique crystalline structure, fortified by elements like chromium and molybdenum, which enhance resistance to corrosion and extreme temperatures. Whether it's a nickel 200 sheet, prized for its purity and ductility, or more complex blends, these materials endure immense stress, making them indispensable in precision engineering and harsh industrial environments.

Unpacking the Strength of Nickel Alloy Sheets

The Science Behind Their Resilience

The fortitude of a nickel alloy sheet is not a mere happenstance but a result of meticulous metallurgical design. At the atomic level, nickel forms a face-centered cubic lattice, which inherently provides ductility and toughness. When alloyed with elements like chromium, molybdenum, or titanium, this structure is further reinforced, creating a matrix that resists deformation under colossal loads. A nickel 200 sheet, composed of 99.6% pure nickel, offers a tensile strength of around 55,000 psi, ideal for applications requiring malleability. In contrast, high-performance alloys like Hastelloy C276 can withstand stresses exceeding 115,000 psi, thanks to their intricate alloying compositions, making them stalwarts in corrosive and high-temperature settings.

Comparing Nickel Alloys to Other Metals

To truly appreciate the vigor of nickel alloy sheets, a juxtaposition with other metals is illuminating. Consider stainless steel, a common industrial material, which typically offers tensile strengths ranging from 75,000 to 95,000 psi. While respectable, it pales in comparison to advanced nickel alloys like Inconel 625, which can endure up to 135,000 psi. Aluminum, another lightweight contender, maxes out at around 45,000 psi, rendering it inadequate for extreme conditions where nickel alloys thrive. This disparity underscores why industries such as aerospace and chemical processing favor nickel-based sheets, as their unparalleled strength ensures longevity and reliability in the most arduous environments.

Real-World Applications Showcasing Strength

The practical manifestations of nickel alloy sheet strength are as diverse as they are impressive. In the aerospace sector, Inconel sheets are integral to turbine blades, enduring temperatures surpassing 1,200°F while resisting mechanical fatigue. In chemical processing, Hastelloy sheets line reactors, shrugging off corrosive acids that would degrade lesser materials. Even a nickel 200 sheet, though softer than its alloyed counterparts, finds its niche in electronics, where its robustness against caustic environments ensures the integrity of sensitive components. These applications highlight not just theoretical strength but a tangible resilience that underpins critical infrastructure across the globe.

Factors Influencing the Durability of Nickel Alloy Sheets

Alloy Composition and Its Impact

The durability of a nickel alloy sheet is profoundly influenced by its elemental makeup. Pure nickel, as found in a nickel 200 sheet, offers commendable corrosion resistance but moderate strength, suitable for less demanding roles. However, introducing alloying elements transforms this base metal into a powerhouse. Chromium enhances oxidation resistance, crucial for high-temperature stability, while molybdenum bolsters resistance to pitting corrosion. Titanium and aluminum, often added to Inconel variants, precipitate strengthening phases, elevating mechanical fortitude. This alchemy of elements ensures that each nickel alloy sheet is tailored to specific challenges, whether it's withstanding cryogenic temperatures or searing heat in industrial furnaces.

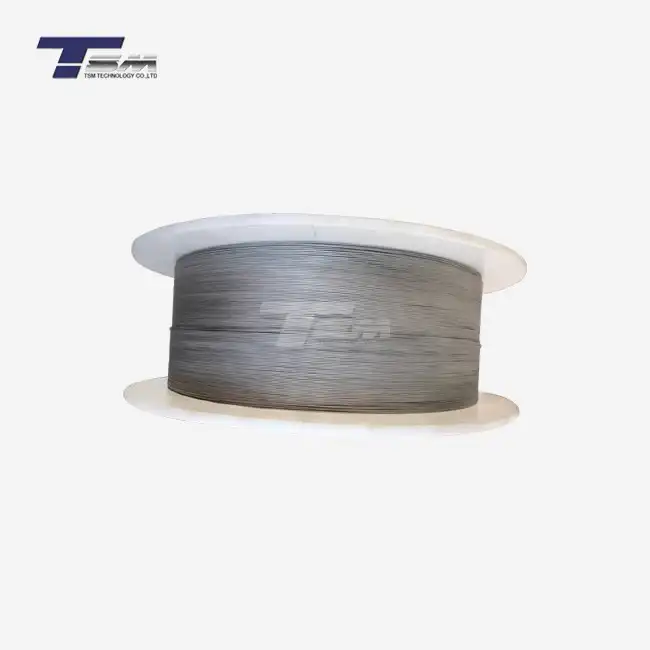

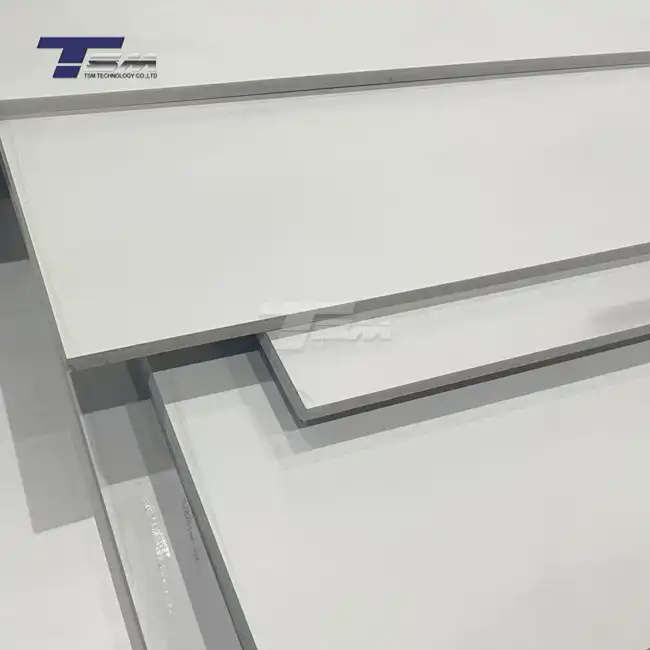

Manufacturing Processes and Quality Control

The journey from raw materials to a finished nickel alloy sheet is fraught with precision, and each step influences its ultimate strength. Advanced techniques like vacuum induction melting ensure purity, eliminating impurities that could weaken the material. Hot rolling and cold working further refine the grain structure, enhancing mechanical properties. At TSM Technology Co., Ltd., every sheet undergoes rigorous scrutiny, with inspectors employing ultrasonic testing and spectrometry to detect flaws. This stringent quality control ensures that each nickel alloy sheet, whether Monel or Hastelloy, meets exacting standards, delivering uncompromised performance to precision engineering and machine shops worldwide.

Environmental Conditions and Performance

The environment in which a nickel alloy sheet operates plays a pivotal role in its longevity. These sheets excel in hostile conditions - think subzero temperatures in LNG plants or the blistering heat of jet engines. Their strength remains unyielding, thanks to a low coefficient of thermal expansion and resistance to creep deformation. In marine environments, where salt water corrodes lesser metals, alloys like Monel 400 shine, maintaining structural integrity over decades. Even under cyclic loading, where fatigue could induce failure, nickel alloys demonstrate remarkable endurance, making them the material of choice for applications where reliability is non-negotiable.

Why Choose Nickel Alloy Sheets for Your Projects?

Longevity and Cost-Effectiveness

Opting for a nickel alloy sheet is an investment in durability and economic prudence. While the initial cost may surpass that of conventional metals, their extended service life offsets this expense. A Hastelloy sheet, impervious to corrosion, can outlast stainless steel by years in aggressive environments, reducing maintenance and replacement costs. Similarly, a nickel 200 sheet, though softer, resists chemical degradation, ensuring consistent performance in specialized applications. This longevity translates to fewer downtimes and enhanced operational efficiency, a boon for industries where every minute of productivity counts.

Versatility Across Industries

The adaptability of nickel alloy sheets is a hallmark of their appeal. In the energy sector, Incoloy sheets withstand the rigors of nuclear reactors, while in pharmaceuticals, their inert nature ensures purity in drug manufacturing. The oil and gas industry relies on Monel sheets for offshore platforms, where resistance to seawater is paramount. Even in niche applications, such as musical instruments, nickel alloys contribute to durability without sacrificing aesthetics. This versatility stems from the ability to tailor alloys to specific needs, ensuring that whether it's a high-strength Inconel sheet or a ductile nickel 200 sheet, there's a solution for every challenge.

TSM Technology's Commitment to Excellence

When selecting nickel alloy sheets, the supplier's expertise is as crucial as the material itself. TSM Technology Co., Ltd., with over a decade of international trading experience since its inception in Hong Kong in 2011, stands as a paragon of reliability. Specializing in superior alloys like Monel, Inconel, Incoloy, and Hastelloy, TSM delivers products shaped to meet the exacting demands of precision engineering. Its relentless pursuit of innovation, coupled with a stringent quality control regimen, ensures that each sheet is a testament to excellence. This dedication positions TSM as a trusted partner for machine shops and industries worldwide.

Conclusion

Nickel alloy sheets, from the ductile nickel 200 sheet to the formidable Inconel, embody strength through their unique compositions and rigorous manufacturing. Their resilience in extreme conditions, versatility across industries, and cost-effectiveness make them indispensable. Whether you're tackling corrosive environments or high-stress applications, these sheets deliver unwavering performance, underpinned by the expertise of suppliers like TSM Technology Co., Ltd.

Contact Us

Ready to harness the strength of nickel alloy sheets for your next project? Contact TSM Technology Co., Ltd. at info@tsm-technology.com to explore our superior alloy solutions and elevate your engineering endeavors.

References

Smith, J. A., & Patel, R. K. (2020). Metallurgical Properties of Nickel-Based Alloys in High-Stress Environments. Journal of Materials Science.

Thompson, L. M. (2019). Corrosion Resistance of Nickel Alloys in Industrial Applications. International Journal of Corrosion Studies.

Nguyen, T. H., & Lee, S. Y. (2021). Advances in Nickel Alloy Manufacturing Techniques. Materials Engineering Review.

Brown, E. D. (2018). High-Temperature Performance of Inconel and Hastelloy Sheets. Aerospace Materials Journal.

Kumar, A., & Singh, P. (2022). Mechanical Strength of Nickel 200 in Cryogenic Conditions. Cryogenics and Materials Research.

Davis, M. R. (2020). Applications of Nickel Alloys in Precision Engineering. Engineering Materials Digest.

Learn about our latest products and discounts through SMS or email