- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Applications of Nickel Alloy Sheet in Industries?

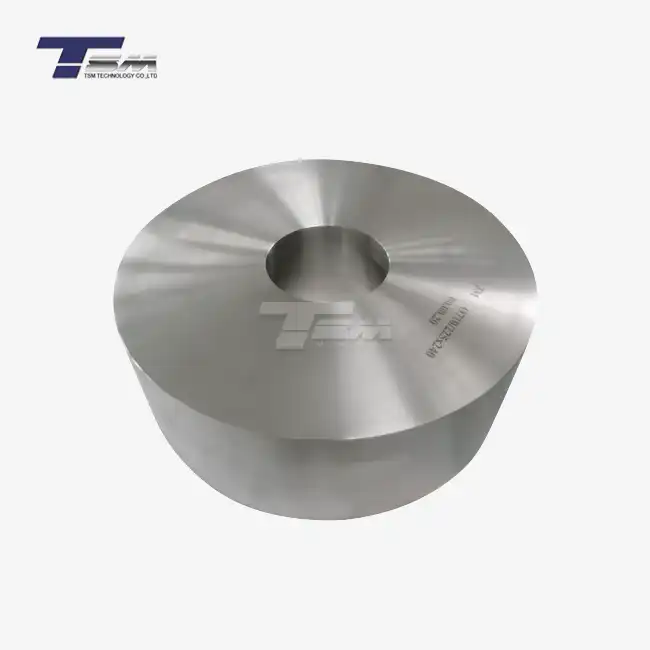

Nickel alloy sheets are versatile marvels in the world of industrial materials, prized for their exceptional durability, corrosion resistance, and ability to withstand extreme environments. These sheets, crafted from superior alloys like Monel, Inconel, Incoloy, and Hastelloy, find applications across a vast array of industries. From aerospace to chemical processing, energy production to marine engineering, their unique properties make them indispensable in precision engineering and machine shops globally. Whether it's a nickel 200 sheet known for its purity and conductivity or other high-performance variants, these materials are engineered to meet the most stringent demands, ensuring reliability and longevity in critical applications.

Unveiling the Versatility of Nickel Alloy Sheets Across Sectors

Nickel alloy sheets are celebrated for their adaptability, making them a cornerstone in industries that demand materials capable of enduring harsh conditions. Let's explore how these remarkable sheets contribute to various sectors, showcasing their indispensable role in modern engineering and manufacturing.

Aerospace: Soaring to New Heights with Durability

The aerospace industry thrives on materials that can endure extreme temperatures, high pressures, and corrosive environments. Nickel alloy sheets, particularly those made from Inconel and Hastelloy, are integral to aircraft engines, turbine blades, and exhaust systems. Their ability to maintain structural integrity at elevated temperatures ensures safety and efficiency in flight. Imagine the intense heat of a jet engine - only materials like these can withstand such conditions without degrading, making them a preferred choice for aerospace engineers aiming to push the boundaries of innovation.

Chemical Processing: Resisting Corrosion in Harsh Environments

In chemical processing plants, exposure to aggressive substances is a daily reality. Nickel alloy sheets, such as those crafted from Monel, excel in resisting corrosion from acids, alkalis, and other corrosive agents. These sheets are often used to fabricate reactors, heat exchangers, and storage tanks, ensuring longevity and safety in operations. A nickel 200 sheet, for example, is particularly valued for its resistance to caustic soda, making it ideal for environments where purity and corrosion resistance are paramount. This resilience translates to reduced maintenance costs and enhanced operational reliability.

Energy Sector: Powering the Future with Reliability

The energy sector, encompassing oil and gas, nuclear power, and renewable energy, relies heavily on materials that can endure extreme conditions. Nickel alloy sheets are used in offshore drilling platforms, nuclear reactors, and solar thermal systems, thanks to their ability to resist stress corrosion cracking and high-temperature oxidation. Incoloy sheets, for instance, are favored in heat exchangers within power plants, ensuring efficient energy transfer even under intense thermal stress. This reliability is crucial for maintaining uninterrupted energy production, making these materials a linchpin in the quest for sustainable energy solutions.

Engineering Excellence: Why Nickel Alloy Sheets Stand Out?

The unique properties of nickel alloy sheets set them apart from other materials, making them a preferred choice for engineers and manufacturers worldwide. Understanding these attributes sheds light on why they are so widely adopted across diverse applications, driving innovation and performance in precision engineering.

Exceptional Strength and Heat Resistance

One of the standout qualities of nickel alloy sheets is their remarkable strength, even at elevated temperatures. Alloys like Inconel are renowned for retaining their mechanical properties in environments exceeding 1000°C, a feat few materials can achieve. This makes them ideal for applications such as gas turbine components and industrial furnaces, where both strength and heat resistance are non-negotiable. The ability to perform under such extreme conditions ensures that machinery and equipment operate efficiently, minimizing downtime and maximizing productivity.

Unmatched Corrosion Resistance

Corrosion is the nemesis of many industrial materials, but nickel alloy sheets rise above this challenge with aplomb. Their resistance to oxidation, pitting, and crevice corrosion makes them indispensable in marine, chemical, and oil and gas applications. For instance, Monel sheets are highly resistant to seawater corrosion, making them a top choice for shipbuilding and offshore structures. Similarly, a nickel 200 sheet offers unparalleled resistance to alkaline environments, ensuring longevity in chemical processing equipment. This durability translates to cost savings and enhanced safety, as equipment remains operational for extended periods without succumbing to degradation.

Versatility in Fabrication and Design

Beyond their physical properties, nickel alloy sheets offer remarkable versatility in fabrication, allowing engineers to craft intricate designs tailored to specific needs. These sheets can be easily welded, machined, and formed into complex shapes, making them suitable for a wide range of applications, from precision components in electronics to large-scale structures in construction. Hastelloy sheets, for example, are often used in the fabrication of pressure vessels due to their ability to maintain integrity under high pressure. This adaptability empowers manufacturers to innovate, creating solutions that meet the exacting standards of modern industry.

Nickel Alloy Sheets in Action: Real-World Applications

To truly appreciate the value of nickel alloy sheets, it's essential to examine their practical applications in real-world scenarios. These examples highlight how these materials solve complex challenges, delivering performance and reliability in demanding environments.

Marine Engineering: Conquering the Seas

The marine environment is notoriously unforgiving, with constant exposure to saltwater, humidity, and fluctuating temperatures. Nickel alloy sheets, particularly those made from Monel, are extensively used in shipbuilding, offshore platforms, and desalination plants. Their resistance to seawater corrosion ensures that critical components, such as propeller shafts and heat exchangers, remain operational for decades. This durability is vital for maintaining the safety and efficiency of maritime operations, where failure is not an option.

Medical Industry: Precision and Purity

In the medical field, precision and purity are paramount, and nickel alloy sheets deliver on both fronts. A nickel 200 sheet, known for its high purity and excellent conductivity, is often used in the manufacture of medical devices, such as MRI scanners and surgical instruments. These sheets are biocompatible and resistant to sterilization processes, ensuring they meet the stringent standards of the healthcare industry. Their role in medical technology underscores their versatility, extending their reach beyond industrial applications to life-saving innovations.

Automotive Innovation: Driving Performance

The automotive industry is transforming, with a growing emphasis on efficiency, sustainability, and performance. Nickel alloy sheets play a pivotal role in this evolution, particularly in the development of electric vehicles (EVs) and high-performance engines. Inconel sheets, for instance, are used in exhaust systems and turbochargers, where their heat resistance enhances engine efficiency. Meanwhile, their corrosion resistance ensures longevity, even in the face of road salt and environmental exposure. This contribution to automotive innovation highlights the role of nickel alloy sheets in shaping the future of transportation.

Conclusion

Nickel alloy sheets are a testament to the power of advanced materials in transforming industries. Their unparalleled strength, corrosion resistance, and versatility make them indispensable in aerospace, chemical processing, energy, marine engineering, and beyond. By choosing high-quality nickel alloy sheets, businesses can enhance performance, reduce maintenance costs, and drive innovation. As industries continue to evolve, these materials will remain at the forefront, meeting the challenges of tomorrow with reliability and excellence.

Contact Us

For more information about our superior nickel alloy products and how they can benefit your industry, please contact us at info@tsm-technology.com. Our team of experts is ready to assist you in finding the perfect nickel alloy solution for your specific needs.

References

Smith, J. A. (2020). Advanced Materials in Aerospace Engineering. New York: Industrial Press.

Patel, R. K. (2019). Corrosion Resistance of Nickel Alloys in Chemical Processing. London: Materials Science Publications.

Thompson, L. M. (2021). High-Temperature Alloys in Energy Production. Chicago: Energy Engineering Press.

Nguyen, T. H. (2022). Marine Applications of Nickel-Based Materials. Singapore: Maritime Technology Review.

Kumar, S. (2020). Nickel Alloys in Medical Device Manufacturing. Boston: Biomedical Engineering Journal.

Brown, E. D. (2023). Innovations in Automotive Materials. Detroit: Automotive Engineering Society.

Learn about our latest products and discounts through SMS or email