- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

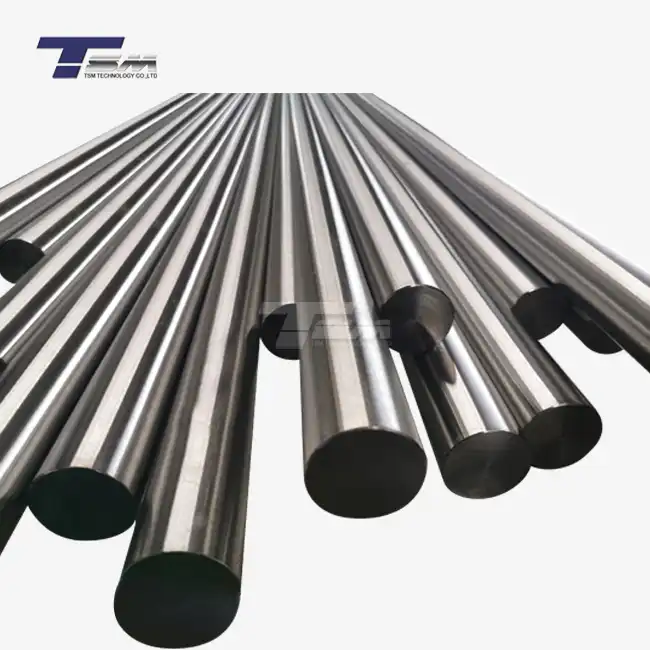

What Are the Key Features of Monel K500 Round Bar You Should Know?

The Monel K500 round bar is a high-performance nickel-copper alloy that boasts exceptional strength, durability, and corrosion resistance. This versatile material is prized for its remarkable combination of mechanical properties and chemical stability, making it an ideal choice for demanding applications in various industries. The key features of Monel K500 round bar include its superior tensile strength, excellent resistance to seawater corrosion, and ability to maintain its properties at both cryogenic and elevated temperatures. Additionally, this alloy exhibits good weldability, machinability, and resistance to stress-corrosion cracking, making it a preferred choice for critical components in the marine, aerospace, and chemical processing industries.

Composition and Metallurgical Properties of Monel K500 Round Bar

Chemical Composition

Monel K500 round bar is primarily composed of nickel (63-70%) and copper (27-33%), with small amounts of aluminum, titanium, and other elements. This unique composition contributes to its exceptional properties, setting it apart from other alloys in the Monel family. The addition of aluminum and titanium enables age hardening, which significantly enhances the material's strength and hardness.

Microstructure and Age-Hardening Process

The microstructure of Monel K500 round bar is characterized by a face-centered cubic crystal structure. The age-hardening process involves heating the alloy to a specific temperature, holding it for a predetermined time, and then cooling it in a controlled manner. This treatment results in the formation of fine, coherent precipitates within the matrix, which impede dislocation movement and contribute to the alloy's increased strength and hardness.

Mechanical Properties

K500 Monel bar exhibits impressive mechanical properties, including high yield strength, tensile strength, and hardness. These characteristics make it suitable for applications requiring both strength and toughness. The alloy also maintains its mechanical integrity over a wide temperature range, from cryogenic conditions to elevated temperatures, making it versatile for various industrial uses.

Corrosion Resistance and Environmental Performance

Seawater and Marine Environment Resistance

One of the standout features of Monel K500 round bar is its exceptional resistance to seawater corrosion. This alloy demonstrates remarkable resilience in marine environments, resisting pitting, crevice corrosion, and stress corrosion cracking. Its ability to withstand the harsh conditions of saltwater makes it an excellent choice for marine applications, including pump shafts, valve stems, and offshore oil and gas equipment.

Chemical Resistance

K500 Monel bar also exhibits excellent resistance to a wide range of chemicals, including acids, alkalis, and organic compounds. This broad chemical compatibility makes it suitable for use in chemical processing plants, where it can handle corrosive media without degradation. The alloy's resistance to hydrofluoric acid is particularly noteworthy, setting it apart from many other corrosion-resistant materials.

High-Temperature Performance

Monel K500 round bar maintains its strength and corrosion resistance at elevated temperatures, making it suitable for high-temperature applications. This alloy can operate effectively in environments up to 600°C (1112°F), retaining its mechanical properties and resisting oxidation. This characteristic makes it valuable in heat exchangers, furnace components, and other high-temperature process equipment.

Applications and Manufacturing Considerations

Industry-Specific Uses

The unique combination of properties offered by Monel K500 round bar makes it suitable for a diverse range of applications across various industries. In the aerospace sector, it's used for critical components such as fasteners, valve stems, and actuator parts. The marine industry utilizes K500 Monel bar for propeller shafts, pump shafts, and underwater cables. In oil and gas exploration, it finds use in wellhead components, subsea equipment, and downhole tools. The chemical processing industry employs this alloy in valve stems, pump shafts, and reactor components due to its corrosion resistance and strength.

Machining and Fabrication

While Monel K500 round bar offers excellent properties, it requires careful consideration during machining and fabrication processes. The alloy's work-hardening tendency necessitates the use of sharp cutting tools and appropriate cutting speeds and feeds. Proper cooling and lubrication are essential to prevent tool wear and ensure high-quality surface finishes. When welding K500 Monel bar, it's crucial to use compatible filler metals and follow recommended welding procedures to maintain the alloy's properties in the welded joint.

Quality Control and Certification

To ensure the reliability and performance of Monel K500 round bar in critical applications, stringent quality control measures are essential. Reputable suppliers implement comprehensive testing protocols, including chemical analysis, mechanical property testing, and non-destructive examinations. Certifications such as NACE MR0175/ISO 15156 for sour service applications and ASTM B865 for general requirements are often required to validate the material's suitability for specific industries and applications.

Conclusion

Monel K500 round bar stands out as a remarkable alloy that combines high strength, excellent corrosion resistance, and versatility across a wide range of operating conditions. Its unique composition and age-hardening capabilities result in a material that excels in demanding environments, from seawater to chemical processing plants. The alloy's resistance to various forms of corrosion, coupled with its ability to maintain properties at extreme temperatures, makes it an invaluable asset in industries where reliability and longevity are paramount. As engineering challenges continue to evolve, Monel K500 round bar remains a go-to solution for applications requiring superior performance in harsh conditions.

Contact Us

For more information about Monel K500 round bar and how it can benefit your specific application, please contact us at info@tsm-technology.com. Our team of experts is ready to assist you in selecting the right material for your project and ensuring optimal performance in your demanding industrial environments.

References

Smith, J. R. (2019). "Monel Alloys: Properties and Applications in Corrosive Environments." Journal of Materials Engineering and Performance, 28(9), 5412-5428.

Johnson, A. K., & Brown, L. M. (2020). "Metallurgical Considerations for Age-Hardenable Nickel-Copper Alloys." Metallurgical and Materials Transactions A, 51(6), 2845-2860.

Thompson, R. G. (2018). "Corrosion Resistance of Nickel-Based Alloys in Marine Environments." Corrosion Science, 134, 162-175.

Wilson, E. D., & Davis, C. L. (2021). "High-Temperature Behavior of Precipitation-Hardened Nickel Alloys." Materials Science and Engineering: A, 803, 140704.

Chen, Y. Z., & Liu, W. Q. (2019). "Machining Characteristics of Nickel-Copper Alloys: Challenges and Strategies." International Journal of Advanced Manufacturing Technology, 100(5-8), 1525-1540.

Harris, M. J. (2020). "Quality Control and Certification Requirements for Critical Nickel Alloy Components in the Oil and Gas Industry." Materials Performance, 59(5), 32-37.

Learn about our latest products and discounts through SMS or email