- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is a Monel 400 Tube?

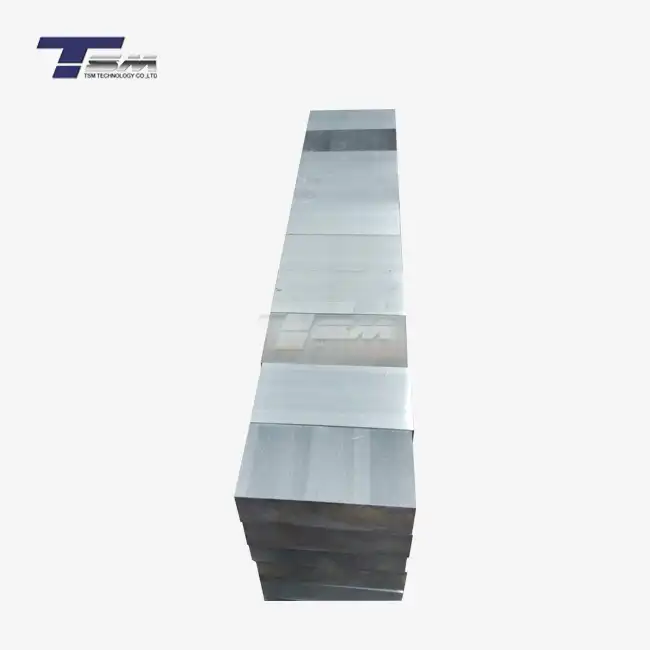

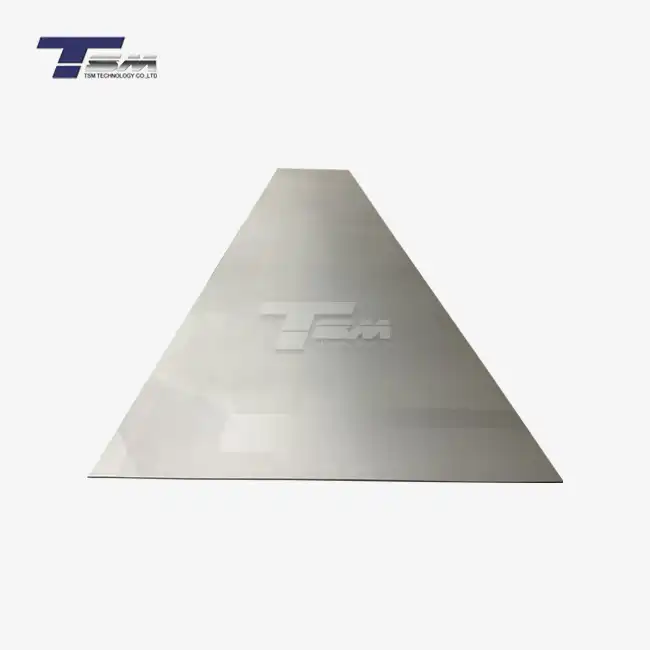

A Monel 400 tube is a seamless or welded cylindrical product crafted from Monel 400, a nickel-copper alloy renowned for its exceptional corrosion resistance and durability. This alloy, composed primarily of nickel (around 67%) and copper (approximately 23%), is celebrated for its ability to withstand harsh environments, including seawater, acids, and alkalis. Monel 400 tubes are widely utilized in industries such as marine engineering, chemical processing, and oil and gas, where reliability under extreme conditions is paramount. Available in various sizes and wall thicknesses, these tubes offer versatility for applications ranging from heat exchangers to piping systems, making them a preferred choice for precision engineering projects globally.

Understanding the Properties of Monel 400 Tubes

Composition and Alloy Characteristics

Monel 400, the foundation of Monel 400 tubes, is a unique alloy that blends nickel and copper with trace amounts of iron, manganese, carbon, and silicon. This composition imparts remarkable corrosion resistance, particularly in saline and acidic environments. Unlike many other metals, Monel 400 tubing maintains its integrity even when exposed to hydrofluoric acid, sulfuric acid, and seawater, making it indispensable in demanding sectors. Its non-magnetic nature further enhances its appeal for specialized applications, such as in electronic components and marine equipment, where magnetic interference must be minimized.

Mechanical Strength and Durability

One of the standout features of Monel 400 tubes is their mechanical robustness. These tubes exhibit high tensile strength, allowing them to endure significant stress without deforming. Additionally, Monel 400 retains its mechanical properties across a wide temperature range, from sub-zero conditions to elevated temperatures up to 1000°F (538°C). This thermal stability, combined with its resistance to stress corrosion cracking, ensures that Monel tubing remains reliable in fluctuating operational environments, such as those encountered in chemical plants or offshore platforms.

Versatility in Fabrication

Monel 400 tubes are prized for their ease of fabrication, which allows manufacturers to tailor them to specific project requirements. Whether seamless or welded, these tubes can be cold-worked, machined, or welded without compromising their structural integrity. This adaptability makes Monel 400 pipe a go-to material for custom-engineered solutions, such as intricate piping networks or heat exchanger systems. The alloy's ability to be formed into various shapes and sizes further underscores its value in precision engineering, where bespoke components are often required.

Applications of Monel 400 Tubes Across Industries

Marine and Offshore Engineering

The marine sector is one of the largest consumers of Monel 400 tubes, thanks to their unparalleled resistance to seawater corrosion. These tubes are integral to the construction of shipboard piping systems, desalination plants, and offshore oil rigs. In environments where exposure to saltwater is constant, Monel tubing outperforms many other materials, resisting pitting and crevice corrosion that can compromise lesser alloys. This durability translates to reduced maintenance costs and extended service life, making it a cost-effective choice for marine applications.

Chemical Processing and Petrochemical Industries

In chemical processing, Monel 400 tubes are essential for handling corrosive substances that would degrade standard materials. From transporting hydrofluoric acid to managing alkaline solutions, Monel 400 pipe excels in environments where other metals falter. Heat exchangers, reactors, and distillation columns often incorporate these tubes due to their ability to withstand both chemical attack and thermal stress. The petrochemical industry also relies on Monel tubing for its resilience in sour gas environments, where hydrogen sulfide can cause embrittlement in less robust materials.

Aerospace and Power Generation

The aerospace and power generation sectors leverage Monel 400 tubes for their high strength-to-weight ratio and thermal stability. In aerospace, these tubes are used in fuel and hydraulic lines, where reliability under extreme conditions is non-negotiable. Similarly, in power plants, Monel 400 pipe is employed in boiler feedwater heaters and steam generators, where it resists corrosion from high-purity water and steam. The alloy's ability to perform consistently in these high-stakes applications underscores its reputation as a material of choice for critical infrastructure.

Manufacturing and Quality Control of Monel 400 Tubes

Alloy Composition and Material Sourcing

The journey of a Monel 400 tube begins with the careful selection of raw materials. Nickel and copper, the primary constituents, are sourced from trusted suppliers to guarantee purity and consistency. Trace elements, such as iron and manganese, are precisely controlled to enhance the alloy's properties. This meticulous approach to composition ensures that the resulting Monel 400 pipe exhibits the desired corrosion resistance, strength, and workability.

Advanced Fabrication Techniques

Fabricating Monel 400 tubes involves sophisticated processes, including hot forging, cold drawing, and seamless welding, depending on the intended application. Seamless Monel tubing, prized for its uniformity and strength, is created through extrusion or piercing, followed by annealing to relieve internal stresses. Welded Monel 400 pipe, on the other hand, is crafted using precision welding techniques, ensuring leak-proof joints and structural integrity. These methods are tailored to meet the specific demands of industries worldwide.

Rigorous Quality Assurance Protocols

Quality control is the bedrock of TSM Technology's operations. Each Monel 400 tube undergoes a battery of tests, including ultrasonic inspection, hydrostatic testing, and dimensional analysis, to verify its performance under real-world conditions. Chemical composition is validated through spectrometry, while mechanical properties are assessed via tensile and hardness tests. This rigorous inspection regime, conducted by seasoned professionals, ensures that every piece of Monel tubing adheres to international standards, delivering reliability and peace of mind to customers.

Conclusion

Monel 400 tubes represent a pinnacle of engineering excellence, blending corrosion resistance, mechanical strength, and versatility to serve a myriad of industries. From marine engineering to chemical processing, their applications underscore their indispensability in challenging environments. At TSM Technology Co., Ltd., the commitment to crafting superior Monel tubing through advanced manufacturing and stringent quality control ensures that customers receive products of unmatched quality. Whether you're exploring Monel 400 pipe for a specific project or seeking a reliable supplier, this alloy offers a solution that stands the test of time.

Contact Us

For more information about Monel 400 tubes and other superior alloy products, please contact TSM Technology Co., Ltd. at info@tsm-technology.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

Special Metals Corporation. "Monel Alloy 400: Technical Bulletin." Special Metals Publication, 2020.

Nickel Institute. "Properties and Applications of Nickel Alloys in Corrosive Environments." Nickel Institute Journal, 2019.

International Organization for Standardization. "ISO 6207: Seamless Nickel and Nickel Alloy Tube Specifications." ISO Standards, 2018.

American Society for Testing and Materials. "ASTM B165: Standard Specification for Nickel-Copper Alloy Seamless Pipe and Tube." ASTM International, 2021.

Marine Engineering Society. "Corrosion Resistance of Nickel Alloys in Seawater Systems." Marine Engineering Review, 2022.

Chemical Processing Magazine. "Advances in Alloy Materials for Chemical Plant Durability." Chemical Processing Journal, 2023.

Learn about our latest products and discounts through SMS or email