- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Applications of Monel K500 Round Bars?

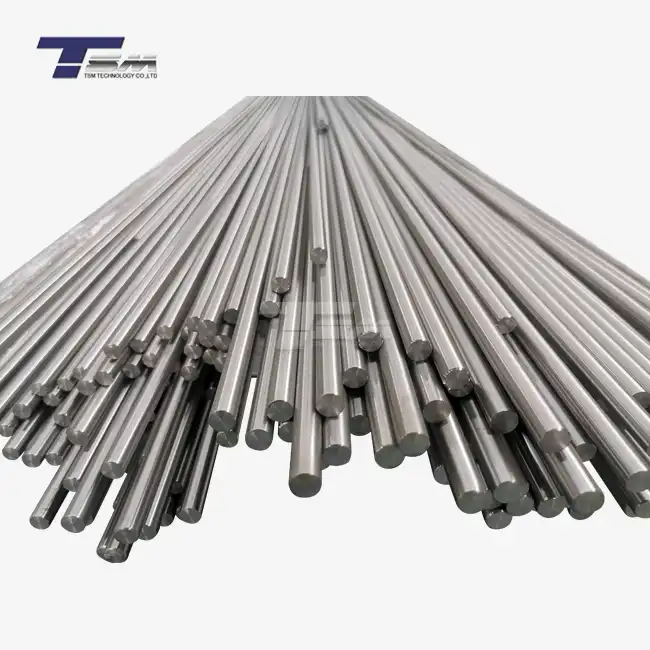

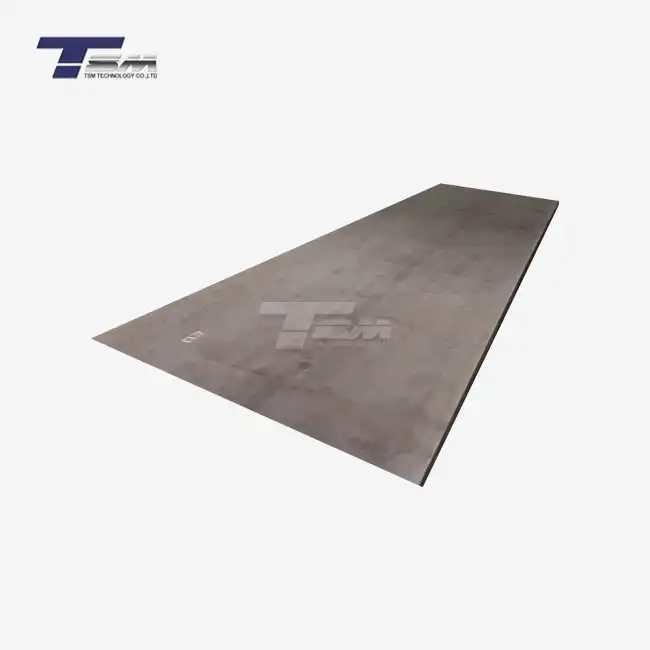

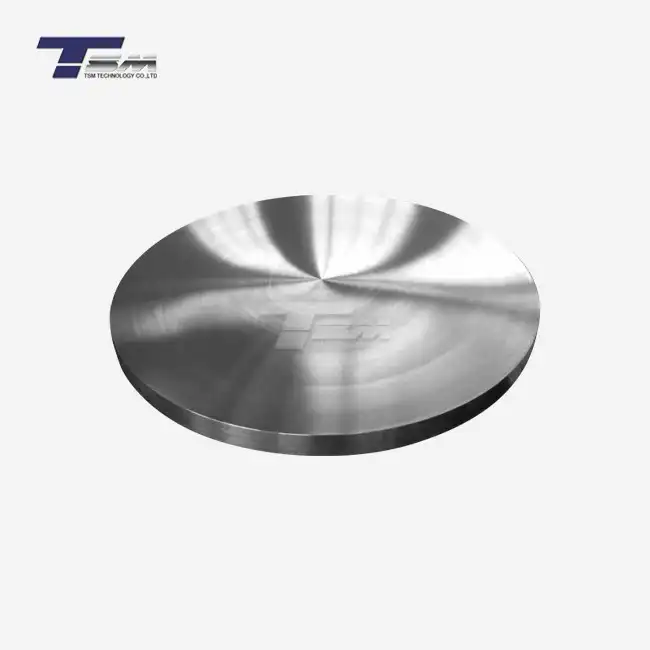

When it comes to superior nickel alloys, Monel K500 stands out as a remarkable material, prized for its exceptional strength, corrosion resistance, and durability. Monel K500 round bars, in particular, are highly sought after in industries that demand reliable performance under extreme conditions. But what exactly are the applications of these robust k500 round bars? These versatile components are integral to marine engineering, aerospace, oil and gas, chemical processing, and even medical equipment manufacturing. Their ability to withstand harsh environments while maintaining structural integrity makes them indispensable across a global spectrum of precision engineering and machine shop applications.

Unveiling the Versatility of Monel K500 Round Bars in Marine Engineering

Monel K500 round bars are celebrated for their unparalleled resilience in marine environments, where exposure to saltwater, humidity, and fluctuating temperatures can wreak havoc on lesser materials. Let's explore how these k500 Monel bars shine in this demanding sector.

Withstanding Corrosion in Seawater Environments

Marine applications often involve constant exposure to saline conditions, which can corrode even the most robust metals. The k500 round bar, however, is engineered to resist pitting, crevice corrosion, and stress corrosion cracking. This makes it an ideal choice for crafting propeller shafts, pump shafts, and valve components that must endure the relentless assault of seawater.

Enhancing Durability in Shipbuilding Components

Shipbuilding requires materials that can handle immense mechanical stress while resisting degradation. Monel K500 round bars are frequently utilized in the construction of fasteners, springs, and chains due to their high tensile strength and fatigue resistance. These properties ensure that critical components remain operational over extended periods, even under punishing marine conditions.

Supporting Offshore Structures

Offshore platforms, such as oil rigs and wind turbines, rely on materials that can endure both environmental and mechanical challenges. The k500 Monel bar is a preferred material for manufacturing bolts, anchors, and other structural elements in these installations. Its ability to maintain integrity in subsea conditions underscores its value in ensuring the longevity and safety of offshore infrastructure.

Harnessing the Strength of Monel K500 Round Bars in Oil and Gas Exploration

The oil and gas industry is synonymous with extreme conditions—high pressures, corrosive substances, and abrasive environments. Monel K500 round bars are a cornerstone in this sector, delivering reliability where failure is not an option. Let's delve into how these k500 round bars are applied in this high-stakes industry.

Thriving in Sour Gas Environments

Sour gas, rich in hydrogen sulfide, is notoriously corrosive, posing significant risks to equipment longevity. The k500 Monel bar excels in such environments, resisting sulfide stress cracking and maintaining its mechanical properties. This makes it a prime candidate for crafting drill collars, valves, and downhole tools that operate in sour gas wells, ensuring operational continuity and safety.

Powering High-Pressure Pumping Systems

Oil and gas extraction often involves high-pressure pumping systems that demand materials capable of withstanding intense mechanical stress. Monel K500 round bars are used to fabricate pump shafts, impellers, and other critical components in these systems. Their combination of hardness and toughness ensures that these parts can handle the rigors of continuous operation without succumbing to wear or fatigue.

Ensuring Reliability in Subsea Equipment

Subsea exploration and production require equipment that can function flawlessly at great depths, where maintenance is challenging and costly. The k500 round bar is integral to the production of subsea connectors, riser bolts, and other fittings. Its resistance to corrosion and erosion in seawater, coupled with its ability to endure high mechanical loads, makes it indispensable for subsea applications, enhancing the reliability of underwater operations.

Exploring the Precision of Monel K500 Round Bars in Aerospace and Beyond

While marine and oil and gas applications highlight the ruggedness of Monel K500 round bars, their utility extends into realms that demand precision and innovation, such as aerospace, chemical processing, and medical equipment manufacturing. Let's uncover how these k500 Monel bars contribute to these cutting-edge fields.

Elevating Aerospace Performance

Aerospace engineering requires materials that can withstand extreme temperatures, mechanical stress, and corrosive environments while maintaining a lightweight profile. Monel K500 round bars are employed in the production of landing gear components, engine fasteners, and other critical parts. Their high strength-to-weight ratio and resistance to thermal fatigue ensure that aircraft can operate safely and efficiently, even under the most demanding flight conditions.

Facilitating Chemical Processing Efficiency

Chemical processing plants handle aggressive substances that can erode standard materials. The k500 round bar is a trusted ally in this industry, used to manufacture reactor vessels, heat exchanger tubes, and valve stems. Its resistance to acids, alkalis, and other corrosive agents ensures that equipment remains operational, minimizing downtime and enhancing the efficiency of chemical production processes.

Advancing Medical Equipment Innovation

In the medical field, precision and reliability are paramount, especially in the production of surgical instruments and diagnostic equipment. Monel K500 round bars are utilized to create components that require exceptional strength and corrosion resistance, such as orthopedic implants and MRI machine fittings. Their biocompatibility and durability make them a valuable asset in advancing medical technology, ensuring patient safety and equipment longevity.

Conclusion

Monel K500 round bars are a testament to the ingenuity of superior nickel alloys, offering a blend of strength, corrosion resistance, and versatility that few materials can match. From the depths of the ocean to the heights of the sky, these k500 Monel bars play a pivotal role in industries that demand excellence. Whether you're navigating marine challenges, exploring oil and gas frontiers, or innovating in aerospace and medical fields, these robust components deliver reliability and performance.

Contact Us

For more information about Monel K500 round bars and how they can benefit your specific application, please contact us at info@tsm-technology.com. Our team of experts is ready to assist you in selecting the right material for your project needs.

References

Smith, J. A., & Thompson, R. L. (2019). Nickel Alloys in Extreme Environments: Applications and Performance. Materials Science Publishing.

Patel, K. M. (2020). Corrosion Resistance of Monel Alloys in Marine Engineering. Journal of Advanced Materials.

Lee, S. H., & Kim, D. W. (2021). High-Strength Alloys in Oil and Gas Exploration. Energy Materials Review.

Brown, E. T. (2018). Aerospace Materials: Innovations in Nickel Alloys. Aviation Engineering Press.

Gupta, R. (2022). Chemical Processing Equipment: Material Selection and Durability. Industrial Chemistry Insights.

Nguyen, T. L., & Martinez, P. (2023). Biocompatible Alloys in Medical Device Manufacturing. Biomedical Engineering Journal.

Learn about our latest products and discounts through SMS or email