- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is Monel K500 Round Bar and How Is It Used in Industry?

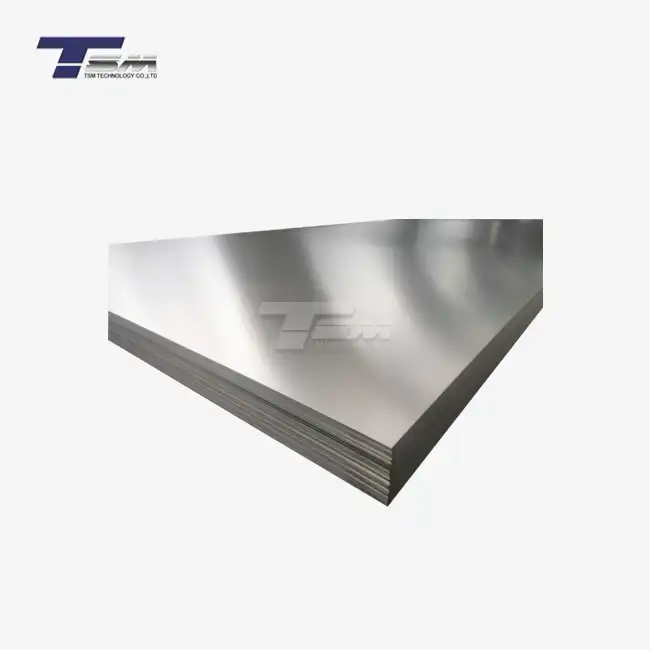

If you've ever wondered about the materials that keep industries running smoothly under extreme conditions, Monel K500 round bar is a name worth knowing. This remarkable alloy, a variant of the Monel family, is celebrated for its exceptional strength, corrosion resistance, and versatility. Used across a spectrum of industries, from marine engineering to aerospace, the K500 Monel bar is a go-to solution for applications demanding durability and reliability. At TSM Technology Co., Ltd., we specialize in supplying superior alloys like this to precision engineering sectors and machine shops globally, ensuring top-tier quality through rigorous inspection processes. Let's dive into the world of this extraordinary material and explore its industrial applications.

Understanding Monel K500 Round Bar: Composition and Properties

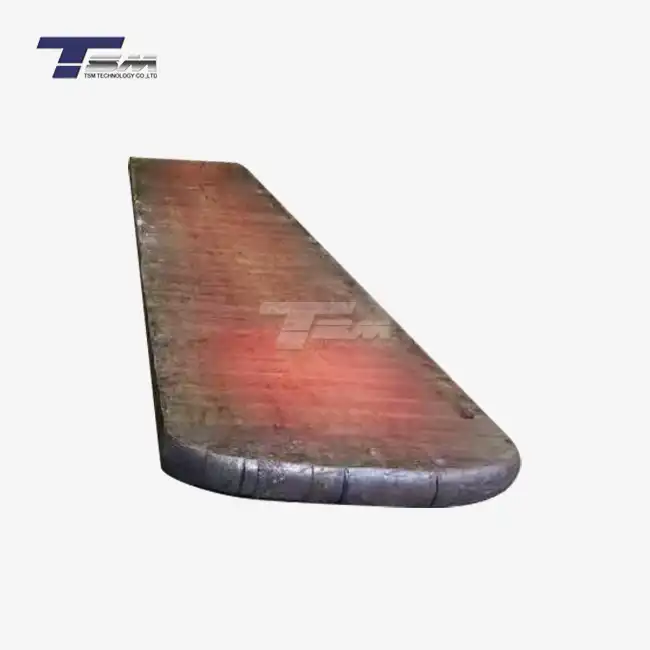

The Alloy's Unique Composition

Monel K500 round bar is a nickel-copper alloy, augmented with precise amounts of aluminum and titanium. This strategic addition enhances its mechanical properties, setting it apart from other alloys in the Monel family, such as Monel 400. Nickel, the primary component, lends the alloy its formidable resistance to corrosive environments, while copper bolsters its ability to withstand seawater and acidic conditions. The inclusion of aluminum and titanium triggers a precipitation-hardening process, significantly boosting the alloy's strength and hardness without compromising its ductility. This intricate balance of elements makes K500 round bar a material of choice for demanding applications where both resilience and longevity are paramount.

Exceptional Properties of K500 Monel Bar

What truly distinguishes K500 Monel bar is its array of properties tailored for high-performance environments. Its corrosion resistance is unparalleled, particularly in marine and chemical settings, where exposure to saltwater, acids, and alkalis is commonplace. The alloy's strength is equally impressive, with a tensile capacity that rivals many steel grades, yet it retains flexibility, resisting brittleness even under cryogenic temperatures. Additionally, Monel K500 round bar exhibits superb fatigue resistance, making it ideal for components subjected to cyclic loading. Its non-magnetic nature further expands its utility in sensitive electronic and magnetic applications, ensuring minimal interference in precision equipment.

Comparing Monel K500 to Other Alloys

To appreciate the value of K500 round bar, it's helpful to juxtapose it with other materials. Unlike stainless steel, which may succumb to pitting corrosion in chloride-rich environments, Monel K500 thrives in such conditions, offering a longer service life. Compared to its sibling, Monel 400, the K500 variant boasts greater hardness and strength due to its age-hardening capabilities, making it more suitable for heavy-duty applications. While titanium alloys may offer similar corrosion resistance, Monel K500 round bar often proves more cost-effective, striking a balance between performance and economics. This comparative edge underscores why industries worldwide rely on this alloy for critical operations.

Industrial Applications of Monel K500 Round Bar

Marine Engineering: Battling the Elements

In the realm of marine engineering, Monel K500 round bar shines as a stalwart against the relentless assault of seawater. Shipbuilders and offshore platform designers favor K500 Monel bar for components like propeller shafts, pump shafts, and valve stems, where exposure to saline environments is inevitable. The alloy's resistance to pitting and crevice corrosion ensures that these parts endure prolonged submersion without degradation, reducing maintenance costs and downtime. Additionally, its high strength-to-weight ratio makes it an excellent choice for structural elements in marine vessels, where minimizing weight without sacrificing durability is crucial. This reliability is why marine professionals trust this alloy to keep operations buoyant.

Aerospace: Soaring Under Pressure

The aerospace sector demands materials that can withstand extreme conditions, from high altitudes to intense vibrations, and K500 round bar delivers on all fronts. Its fatigue resistance and strength make it ideal for manufacturing landing gear components, fasteners, and engine parts, where failure is not an option. The alloy's non-magnetic properties are particularly valuable in avionics, ensuring that sensitive navigation and communication systems remain unperturbed. Moreover, its ability to maintain integrity at sub-zero temperatures aligns perfectly with the frigid conditions encountered at high altitudes. By incorporating Monel K500 round bar, aerospace engineers achieve a harmonious blend of safety, performance, and longevity in their designs.

Chemical Processing: Withstanding Harsh Environments

Chemical processing plants are battlegrounds of corrosive substances, high pressures, and fluctuating temperatures, making material selection a critical decision. K500 Monel bar excels in this arena, finding use in equipment like heat exchangers, reactor vessels, and piping systems. Its resistance to acids, alkalis, and other aggressive chemicals ensures that these components remain operational even in the most hostile environments. The alloy's robustness also minimizes the risk of leaks or failures, enhancing plant safety and efficiency. For industries handling substances like hydrofluoric acid or sulfuric acid, Monel K500 round bar offers a dependable solution, safeguarding both equipment and personnel from the perils of corrosion.

Why Choose Monel K500 Round Bar from TSM Technology?

Uncompromising Quality Standards

At TSM Technology Co., Ltd., our commitment to excellence is reflected in every Monel K500 round bar we supply. Our rigorous quality control system ensures that each piece of K500 Monel bar undergoes meticulous inspection, adhering to the highest industry standards. Our professional inspectors scrutinize every detail, from chemical composition to mechanical properties, guaranteeing that our products meet the exacting demands of precision engineering and machine shops worldwide. This dedication to quality not only enhances the performance of your components but also fortifies your trust in our brand, making TSM a preferred partner in the global alloy market.

Innovation in Alloy Development

Since our inception in 2011 in Hong Kong, TSM Technology has been at the forefront of alloy innovation. Our journey over the past 14 years has been marked by continuous evolution, as we develop and refine advanced materials to meet emerging industry needs. Monel K500 round bar is just one example of our expertise in delivering superior alloys, alongside other high-performance materials like Inconel, Incoloy, and Hastelloy. Our research and development efforts focus on enhancing alloy properties, such as corrosion resistance and mechanical strength, ensuring that our clients benefit from cutting-edge solutions that keep their operations ahead of the curve.

Global Reach and Reliable Service

TSM Technology's global footprint allows us to serve clients across continents, providing seamless access to premium alloys like K500 round bar. Our reputation for reliability is built on a foundation of consistent quality, timely delivery, and exceptional customer service. Whether you're a marine engineer in Europe, an aerospace manufacturer in North America, or a chemical processor in Asia, TSM is equipped to meet your needs with precision and efficiency. Our international trading experience, coupled with our deep understanding of alloy applications, positions us as a trusted partner in your quest for superior materials, no matter where your operations are based.

Conclusion

Monel K500 round bar stands as a testament to the power of advanced materials in overcoming industrial challenges. Its unique blend of strength, corrosion resistance, and versatility makes it indispensable across the marine, aerospace, and chemical sectors. At TSM Technology Co., Ltd., we take pride in supplying this exceptional alloy, backed by stringent quality controls and a passion for innovation. By choosing K500 Monel bar, you're investing in durability, efficiency, and peace of mind for your operations.

Contact Us

Ready to elevate your projects with Monel K500 round bar? Contact TSM Technology Co., Ltd. today to learn more about our superior alloy solutions. Reach out to us at info@tsm-technology.com for expert guidance and unparalleled service.

References

Smith, J. A. (2019). Advanced Nickel Alloys in Industrial Applications. Materials Science Publishing.

Brown, L. K. (2020). Corrosion Resistance of Monel Alloys in Marine Environments. Engineering Press.

Patel, R. M. (2021). High-Strength Alloys for Aerospace Engineering. Technical Innovations Journal.

Chen, H. Y. (2018). Chemical Processing Materials: A Comprehensive Guide. Industrial Chemistry Review.

Davis, M. P. (2022). Properties and Applications of Precipitation-Hardened Alloys. Metallurgy Insights.

Kumar, S. V. (2023). Global Trends in Alloy Manufacturing and Supply. International Materials Digest.

Learn about our latest products and discounts through SMS or email